So I believe that the settings have a lot do do with even some quality test. If you think HATCHBOX is not good I have only had this Printed for under a Month and have no knowledge of 3D Printing,Īside from this past Month. Here are my results with those settings and 3.00mm ABS filament from HATCHBOX. NullBlox - Lulzbot TAZ5 3. (2.78 KB)Įnjoy! And please let me know your results. These settings should work for the 5.0mm head and a TAZ5 Lulzbot printer. Here is my working 5.0mm TAZ5 Simplify 3D settings. Sorry if this is a bit over the top… but I thought I’d share what I’ve experimented with in hopes to spark other suggestions. This lets me print closer to the bed, creating a smooth bottom to the projects… and still letting my remove.

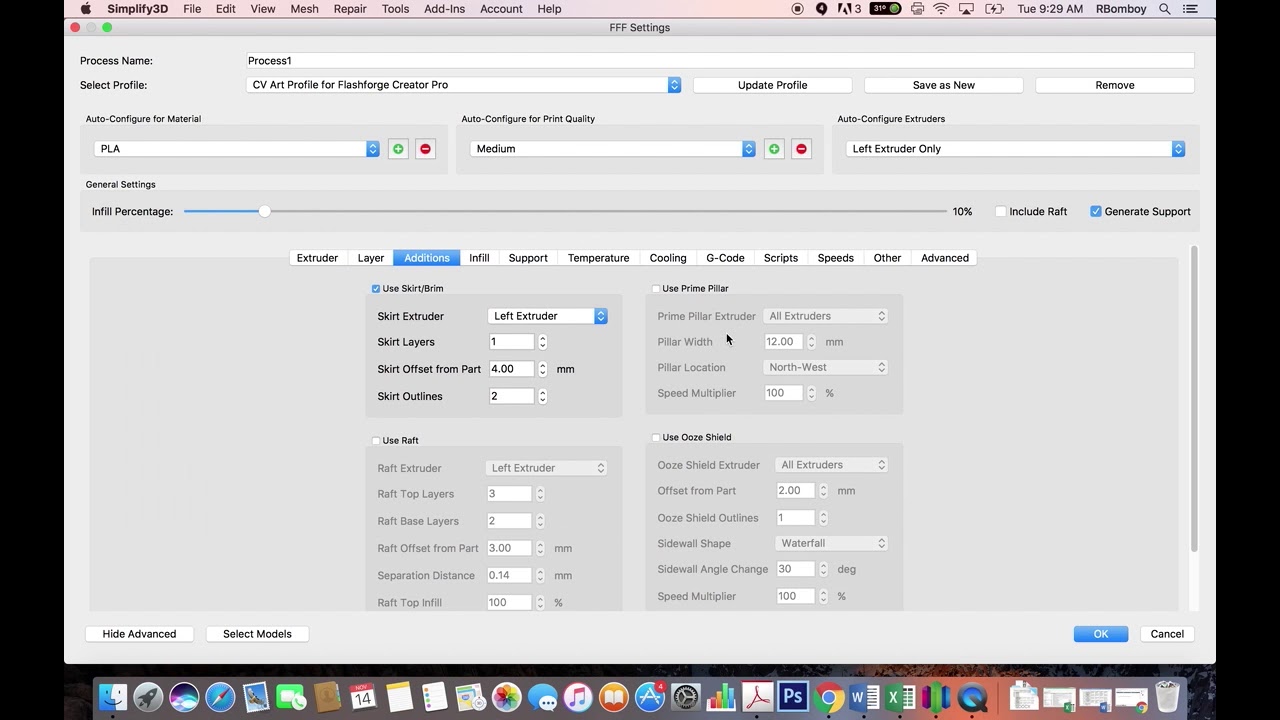

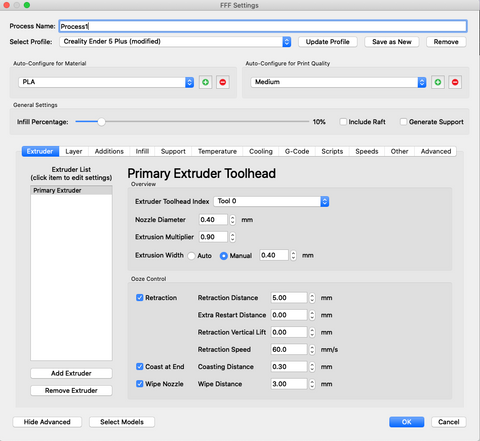

I like to lightly coat the print area with lithium grease, and wipe off every so often. It may make your ABS prints stick too well to the PEI. 2 which may be too close for other printers. Note check, the Z-offset GCode… I may have a default for my printer of. Increased overlap from default to 35%, which also affected a decrease in the extrusion multiplier.Vary heat bed with an initial of 110C to about 3mm, then 100C and eventually to 90C.Achieve a consistent outer shell (top/bottom layers and perimeter).Basic premise behind the various profiles:.Brim/Skirt is modified also for my print environment.Supports are modifed to be very sparse with a dense upper and lower boundary for easy removal.Consistent cooling parameters at set heights, which is optimal for my print environment for ABS… YMMV.For speed, maintain an outline underspeed of 2500 for default speeds of 4200, 48.For color, the extrusion multiplier is changed.5mm and ABS (I didn’t touch the profiles for PLA, Nylon…) It capitalizes on the flexibility of the “Autoconfigure Quality/Material” dropdowns for varying print situation with the.

I attached the following FFF to a different thread, but thought I’d provide here also. Just need the patience for the longer print durations. The default print speed also comes in play for solid infills and inside perimeters, lowering will provide the most desirable finishes. You’ll need to calculate the underspeed percentage to achieve that… so if printing default speed of 5400mm/s use 46%, and 4200mm/s would be 60%. The outline speed of 2500mm/s seems to work well for ABS. To get rid of the zits (not sure of what zippers are), is really just slowing the print speed down.

0 kommentar(er)

0 kommentar(er)